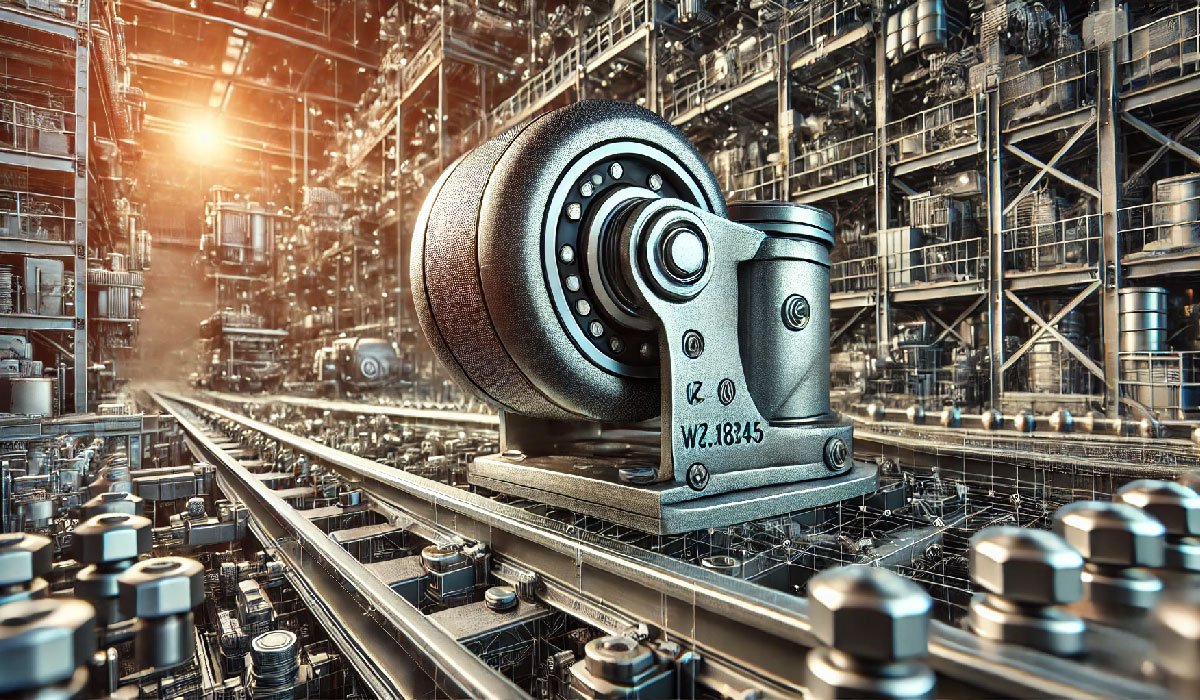

Ball casters are a pivotal component in numerous industries, facilitating smooth, multidirectional movement. At its core, a ball caster consists of a spherical ball enclosed in a housing, allowing it to rotate freely in any direction. This mechanism significantly reduces friction, making it ideal for applications where quick and easy maneuverability is essential. The specific model we are discussing today, the Ball Caster Wz 8.18345 – K 400 Of, stands out due to its exceptional engineering and adaptability across various platforms.

This article aims to provide a detailed exploration of this model, highlighting its unique design, functionality, and applications. By delving into the nuances of this advanced ball caster, readers will gain a comprehensive understanding of its impact on enhancing operational efficiency and innovation in material handling.

Section 1: The Essence of Ball Casters

1.1 Defining the Ball Caster

A ball caster facilitates ease of movement by incorporating a free-rotating ball in a fixed housing, typically made from materials like steel, nylon, or other polymers, which are selected based on their durability and friction properties. The design allows objects mounted on the casters to glide effortlessly over various surfaces without directional constraints. The choice of material not only affects the durability but also the suitability of the ball caster for different environmental conditions and load-bearing requirements.

1.2 Historical Development and Technological Advancements

The concept of the ball caster has evolved significantly since its inception. Initially designed for light-duty applications such as furniture and office equipment, modern ball casters like the Wz 8.18345 – K 400 Of are the result of continuous improvements in material science and mechanical engineering. These advancements have expanded their usability into more demanding industrial applications, where high strength and enhanced load-bearing capabilities are crucial.

Section 2: Unveiling the Ball Caster Wz 8.18345 – K 400 Of

2.1 Design and Construction

The Ball Caster Wz 8.18345 – K 400 Of is meticulously crafted with precision engineering. It features robust housing that supports a large, hardened steel ball, capable of sustaining substantial loads without deformation. The precise dimensions ensure minimal play within the housing, which enhances the caster’s response to movement and increases its efficiency under load.

2.2 Key Features and Technological Enhancements

Precision Engineering and Robustness

The engineering behind the Wz 8.18345 – K 400 Of focuses on achieving high tolerance and minimal wear over time, even under rigorous use. This is accomplished through the use of precision machining tools that ensure each component fits seamlessly for optimal performance.

Load Capacity

This model boasts a high load capacity, designed to distribute weight evenly and maintain stability. This feature is particularly beneficial in applications involving heavy machinery and equipment, where traditional casters might fail or wear quickly.

360-Degree Mobility

Unlike traditional fixed-wheel casters, the 360-degree movement provided by the Wz 8.18345 – K 400 Of offers unmatched maneuverability, making it ideal for tight spaces and complex routing paths in manufacturing facilities or warehouses.

Durability and Material Strength

Constructed from high-grade alloys, the Wz 8.18345 – K 400 Of is built to withstand not only the pressure and weight but also corrosive environments, which makes it suitable for both indoor and outdoor applications.

Section 3: Comprehensive Benefits of Using Ball Caster Wz 8.18345 – K 400 Of

3.1 Enhancing Efficiency and Performance

The design of the Wz 8.18345 – K 400 Of significantly reduces friction, which in turn decreases the energy required to move equipment. This efficiency is critical in production lines and logistics, where speed and ease of movement directly impact operational throughput.

3.2 Ensuring Reliability and Longevity

The durability of the materials used in this model provides a long service life while maintaining consistent performance. This reliability is crucial for industries where equipment downtime can lead to significant financial losses.

3.3 Adaptability Across Various Applications

The versatile design of the Wz 8.18345 – K 400 Of makes it suitable for a broad range of applications, from industrial machinery to mobile platforms in retail environments. Moreover, the availability of customization options allows for its integration into specialized equipment without substantial modifications.

People Read Also: Explore eWorldExternal.com: Your Ultimate Guide to Tech Products and Connectivity Solutions

Section 4: Real-World Applications of Ball Caster Wz 8.18345 – K 400 Of

4.1 Industrial Machinery

In heavy manufacturing sectors, the Ball Caster Wz 8.18345 – K 400 Of facilitates the smooth transfer of large and heavy components across factory floors, enhancing operational efficiency and safety.

4.2 Robotics and Automation

In the field of robotics, this ball caster model enables precise and flexible movement, essential for the accurate positioning of robots and automated systems, particularly in assembly and packaging lines.

4.3 Retail and Healthcare Applications

In retail, the caster improves the maneuverability of display units and storage racks, enhancing the shopping experience by allowing for easier layout adjustments. In healthcare, it contributes to the mobility of medical equipment, aiding in patient care without disrupting the sensitive environment of healthcare facilities.

Section 5: Implementing and Maintaining the Ball Caster Wz 8.18345 – K 400 Of

5.1 Installation Guide

Proper installation begins with selecting the appropriate caster for the load and environment, followed by securing the caster to the equipment using the recommended fittings, ensuring that it functions correctly from the outset.

5.2 Maintenance Strategies

Regular maintenance, such as cleaning the ball and its housing and checking for wear or damage, ensures prolonged efficiency and reliability. Proper lubrication and load management also play critical roles in maintaining the caster’s performance.

Conclusion

The Ball Caster Wz 8.18345 – K 400 Of exemplifies the fusion of innovative design with functional excellence, providing a versatile solution that meets the dynamic demands of modern industries. Its development from a simple component to a critical part of industrial, retail, and healthcare operations underscores its significance in improving operational efficiencies and adapting to various environmental challenges.

FAQs About Ball Caster Wz 8.18345 – K 400 Of

What is the Ball Caster Wz 8.18345 – K 400 Of?

The Ball Caster Wz 8.18345 – K 400 Of is a high-performance ball caster designed for multidirectional movement in demanding environments. It features a robust design, high load capacity, and exceptional durability, making it suitable for industrial machinery, robotics, and other applications where smooth, precise movement is critical.

What materials are used in the Ball Caster Wz 8.18345 – K 400 Of?

This ball caster is typically constructed from high-strength materials, including hardened steel for the ball and various alloys and composites for the housing. These materials are chosen for their durability, resistance to wear and corrosion, and ability to handle heavy loads.

What is the load capacity of the Ball Caster Wz 8.18345 – K 400 Of?

The Ball Caster Wz 8.18345 – K 400 Of is engineered to support significant weight, though the exact load capacity can vary based on the specific model and configuration. Users should consult the manufacturer’s specifications to determine the appropriate load capacity for their particular application.

Can the Ball Caster Wz 8.18345 – K 400 Of be customized?

Yes, customization options are available for the Ball Caster Wz 8.18345 – K 400 Of to meet specific industrial needs. This can include variations in ball material, housing treatment, and mounting options to accommodate different environmental conditions and operational requirements.

How does the 360-degree mobility feature benefit its users?

The 360-degree mobility allows the ball caster to move freely in any direction, enhancing maneuverability and operational efficiency. This is particularly beneficial in tight spaces and complex logistical operations, where traditional fixed-direction casters may not suffice.

What are the primary applications of the Ball Caster Wz 8.18345 – K 400 Of?

The Ball Caster Wz 8.18345 – K 400 Of is widely used in various sectors, including industrial machinery, automotive assembly lines, robotics, retail setups, and healthcare facilities. It excels in environments requiring robust, precise, and flexible movement solutions.

How should the Ball Caster Wz 8.18345 – K 400 Of be maintained?

Regular maintenance for the Ball Caster Wz 8.18345 – K 400 Of includes periodic cleaning to remove debris and prevent jamming, lubrication to ensure smooth movement, and inspections for wear and damage. Adhering to these maintenance practices will extend the life and performance of the caster.

Are there any safety considerations for using the Ball Caster Wz 8.18345 – K 400 Of?

Users should ensure that the ball caster is properly installed and regularly inspected to avoid accidents related to equipment failure. Additionally, it is important to not exceed the recommended load capacity as it can compromise the caster’s performance and safety.

Where can I purchase the Ball Caster Wz 8.18345 – K 400 Of?

The Ball Caster Wz 8.18345 – K 400 Of can be purchased through authorized distributors and suppliers specializing in industrial hardware. For specific purchasing options, contacting the manufacturer directly or visiting their website is recommended.

What warranty is offered with the Ball Caster Wz 8.18345 – K 400 Of?

Warranty terms for the Ball Caster Wz 8.18345 – K 400 Of vary by supplier and region. Typically, a manufacturer will offer a warranty that covers defects in materials and workmanship. Users should review the warranty details provided at the time of purchase for specific coverage information.